+8613394156633

+8613394156633 +8618753175317

+8618753175317 +8613364256389

+8613364256389 carolyn.shi@resterchem.com

carolyn.shi@resterchem.com 18753175317,13364256389,18842852758

18753175317,13364256389,18842852758

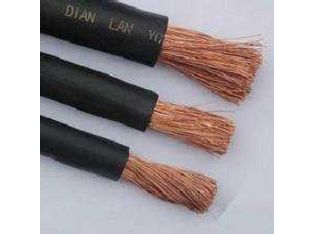

General Cable-sheath Rubber Compound

This series of rubber material implement the standards of GB/T5013-2008 nominal voltage 450/750V (or below),among, TY suit SE3,TYW suit SE4,TYH is special material for electric welding machine. The traditional general…

This series of rubber material implement the standards of GB/T5013-2008 nominal voltage 450/750V (or below),among, TY suit SE3,TYW suit SE4,TYH is special material for electric welding machine.

The traditional general rubber sheathed cable sheath made of natural rubber and styrene-butadiene rubber mixture, early cure easily occur when in use, the problem of cable aging poor etc.. CPE rubber compound not only physical properties can meet the standard requirements, but also has the flame retardant performance, weather resistance, the appearance of fine bright, can greatly prolong the service life of the outdoor cable.

0010010 nbsp;

Performance comparison

| Test item | Unit | TY (SE3) | 0010010 nbsp; | TYW (SE4) | 0010010 nbsp; | TYH(Electric welding machine) | |||||

| GB5013 -2008 | Test value | 0010010 nbsp; | GB5013 -2008 | Test value | 0010010 nbsp; | GB5013-2008 | Test value | ||||

| Before ageing | Tensile strength | Intermediate | MPa | ≥7.0 | 8.0 | 0010010 nbsp; | ≥10.0 | 11.2 | 0010010 nbsp; | ≥12.5 | 13.8 |

| Elongation at | Intermediate | % | ≥300 | 410 | 0010010 nbsp; | ≥300 | 450 | 0010010 nbsp; | ≥300 | 470 | |

| Heat ageing test of air box | Aging conditions | Temperature | ℃ | 70±2 | 0010010 nbsp; | 70±2 | 0010010 nbsp; | 70±2 | |||

| Time | h | 10×24 | 0010010 nbsp; | 10×24 | 0010010 nbsp; | 10×24 | |||||

| Tensile strength | Intermediate | MPa | — | — | 0010010 nbsp; | — | — | 0010010 nbsp; | — | — | |

| Rate of change | % | ≤±20 | -8 | 0010010 nbsp; | ≤±15 | -3 | 0010010 nbsp; | ≤±20 | -5 | ||

| Tensile strength | Intermediate | % | ≥250 | 355 | 0010010 nbsp; | ≥250 | 410 | 0010010 nbsp; | ≥250 | 425 | |

| Rate of change | % | ≤±20 | -13.4 | 0010010 nbsp; | ≤±25 | -9 | 0010010 nbsp; | ≤±20 | -9.5 | ||

| Hot set test | Test conditions | Test temperature | ℃ | 200±3 | 0010010 nbsp; | 200±3 | 0010010 nbsp; | 200±3 | |||

| Load time | min | 15 | 0010010 nbsp; | 15 | 0010010 nbsp; | 15 | |||||

| Mechanical stress | MPa | 0.2 | 0010010 nbsp; | 0.2 | 0010010 nbsp; | 0.2 | |||||

| Load elongation | % | ≤175 | 45 | 0010010 nbsp; | ≤175 | 40 | 0010010 nbsp; | ≤175 | 55 | ||

| Permanent deformation after cooling | % | ≤25 | 15 | 0010010 nbsp; | ≤25 | 10 | 0010010 nbsp; | ≤25 | 10 | ||

| Oil test | Test conditions | Oil temperature | ℃ | 0010010 nbsp; | 0010010 nbsp; | 100±2 | 0010010 nbsp; | 100±2 | |||

| Dipping oil | h | 0010010 nbsp; | 0010010 nbsp; | 24 | 0010010 nbsp; | 24 | |||||

| Tensile strength | Rate of change | % | 0010010 nbsp; | — | 0010010 nbsp; | ≤±40 | -18 | 0010010 nbsp; | ≤±40 | -5 | |

| Elongation at | Rate of change | % | 0010010 nbsp; | — | 0010010 nbsp; | ≤±40 | -25 | 0010010 nbsp; | ≤±40 | -10 | |

| Low temperature test | Brittle temperature | ℃ | 0010010 nbsp; | — | 0010010 nbsp; | — | -40 | 0010010 nbsp; | 0010010 nbsp; | — | |

| Bending test | Temperature | ℃ | 0010010 nbsp; | — | 0010010 nbsp; | -35±2 | No crack | 0010010 nbsp; | 0010010 nbsp; | — | |

| Time | h | 0010010 nbsp; | 0010010 nbsp; | 16 | 0010010 nbsp; | 0010010 nbsp; | |||||

Hot Tags: general cable-sheath rubber compound, China, manufacturers, suppliers, factory, producers, customized, low price, free sample